Brushes for cleaning offset printing plates and sheets

Brushes for cleaning offset printing plates and sheets

Cleaning of offset printing plates and sheets

Within the printing, paper and cardboard industry, our brushes are used in almost all processes. Brushes are essential in rotary, flexographic and offset printing, as well as in pre- and post-printing applications. Especially in automated production processes, our brushes play an important role in achieving a perfect result.

We offer different types of brushes depending on their application and press model. All our brushes can be manufactured according to customer specifications: from the material to the dimensions. The most commonly used brushes are:

• Spiral cylindrical brushes for cleaning and washing.

• Roller brushes with inserted fibre tufts for cleaning and washing.

• Roller brushes for plate processors.

• Modular cylindrical brushes for washing.

• Strip and plate brushes for guiding, driving and washing.

• Strip brush strips for sealing.

Brushes for all types of press models and machines. Due to the wide variety of brushes, our brushes are available to suit all types and models of presses and machines. We are the preferred supplier to some of the big names in the printing industry. Our brushes are manufactured from high-quality materials and fully automated production machines.

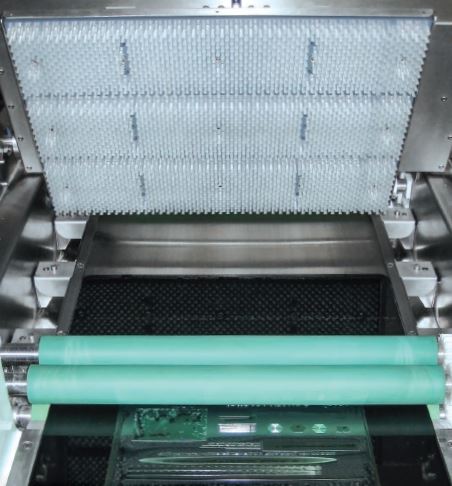

Spiral brushes & Tufted cylindrical brushes

Cylindrical brushes for cleaning and washing

• Suitable for cleaning units for all types of machines in the printing industry.

• Various brush qualities for different cleaning operations.

• Both spiral and tufted brush designs are possible; it is also possible to refill existing brush cores.

Main applications:

• Cleaning of offset printing plates, offset plates, tapes and cylinders.

• Washing of rubber blankets for printing.

The advantages:

• High performance and results: in our experience, spiral roller brushes deliver the best results when washing and cleaning press cylinders and rubber blankets due to the maximum density of the brush surface.

• Long brush life, cost-effective.

• Reduces downtime.

Quality

The brushes are manufactured in-house. This allows us to verify quality in accordance with our high standards.

Cylindrical Brushes for Humidifying and Moistening

• Suitable for high speeds.

• Applicable in humidification units of all types of offset press machines.

• Excellent dampening distribution due to the compact density of the brush and the use of special fibres.

Main application:

• Humidification/moistening impression plates (moistening rollers/dampers).

The advantages:

• Areas that do not require printing are efficiently dampened.

• Less wear on printing plates.

• Greater colour stability thanks to improved water-ink balance.

Modular toothed cylindrical brushes

For quick or partial changes.

• Several standard sizes available.

Main application:

• Cleaning and washing of flexographic printing plates.

The advantages:

• Better results from printing plates.

• High durability and low moisture absorption due to the use of high-quality materials. Many types of materials possible.

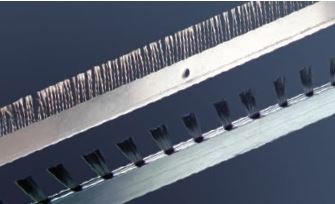

Strip brushes and brush plates

Brushing strips and plates for guiding, driving and washing

• Suitable for roller offset printing machines, folding machines, binding machines and printing plate washing units.

• Available in any shape and size; fibreglass-reinforced materials can also be used.

• Often made of synthetic materials in various dimensions; for special applications, it is possible to sand the tips of the fibres for even better results.

Main applications:

• Guiding, holding, supporting and handling paper and cardboard.

• Avoiding excessive braking of the paper sheet.

• Washing and cleaning flexographic printing plates.

The advantages:

• Increased performance due to optimal paper flow.

• No damage to products.

• Reduced downtime and cost savings.

• Improved printing plate results.

Other types of brushes for the printing industry

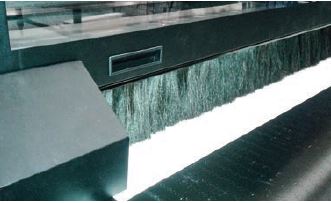

Antistatic brushes for discharging static electricity

• Available in various designs such as strip brushes, slat brushes, roller brushes, plug brushes, and special designs.

Main application:

• Prevention or elimination of static charges during paper handling.

The advantages:

• No static build-up.

• No more disruptions during the production process, therefore saving costs.

Strip brush strips for sealing machines

• Available in various dimensions, densities, and profiles.

Main application:

• Sealing openings and gaps in machines or machine parts; blocking light or preventing the ingress of dust and dirt.

The advantages:

• Bright light in printing applications is blocked.

• No more jams and blockages due to dust and dirt, for example in the engine room.

• Reduces downtime and saves costs.