Flexible Sliding Brush Move Parts Reduce Noise

Flexible Sliding Brush Move Parts Reduce Noise

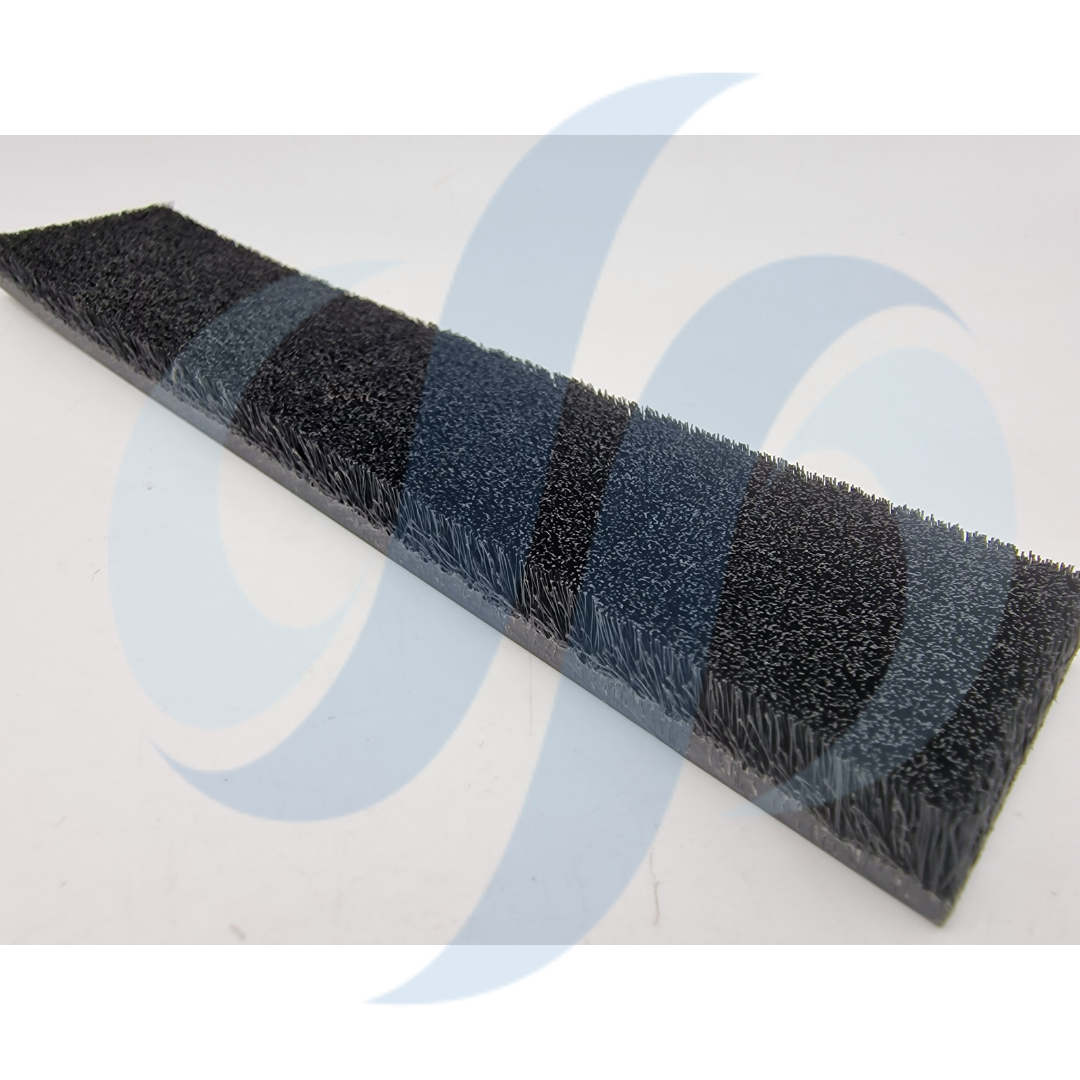

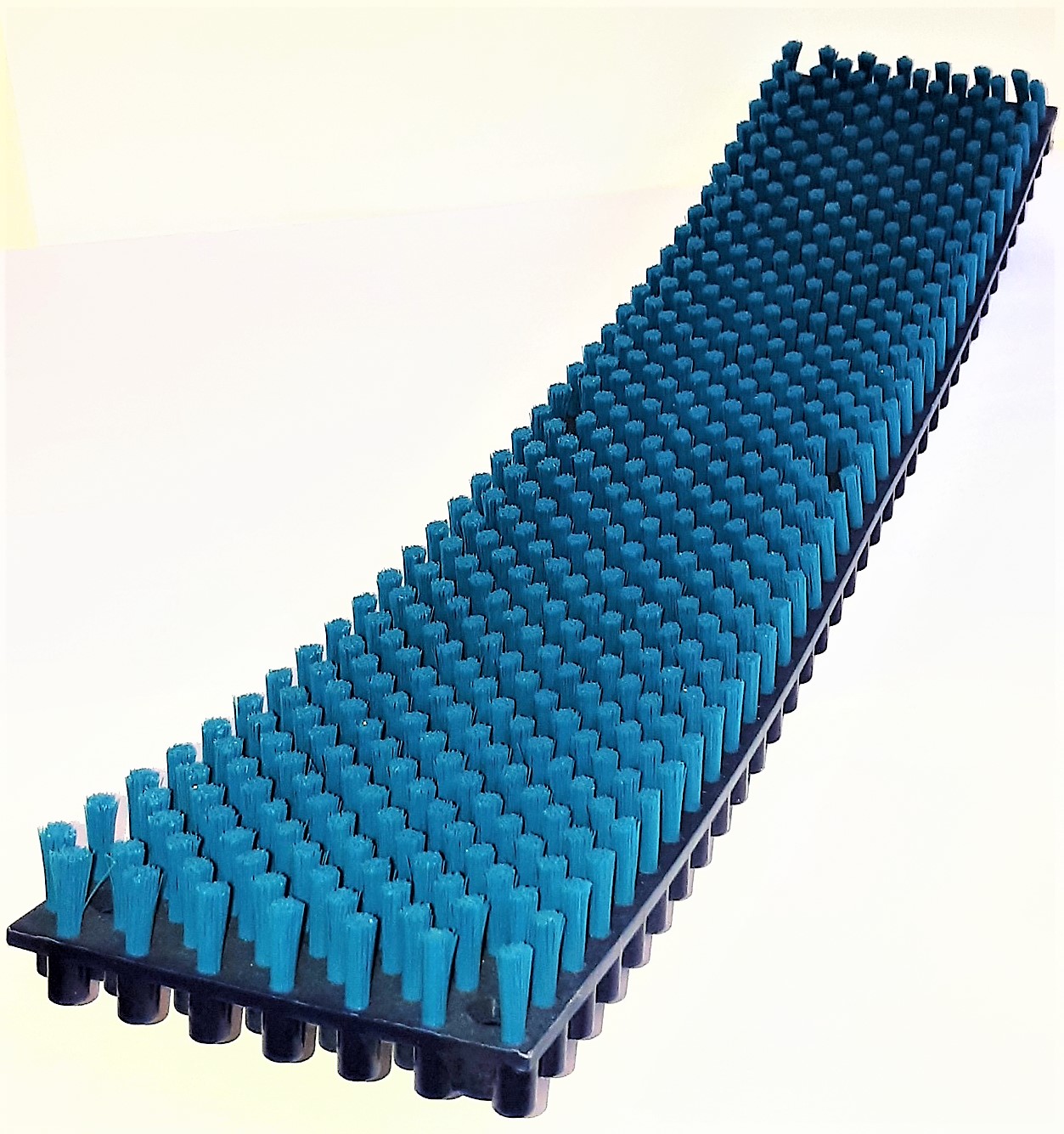

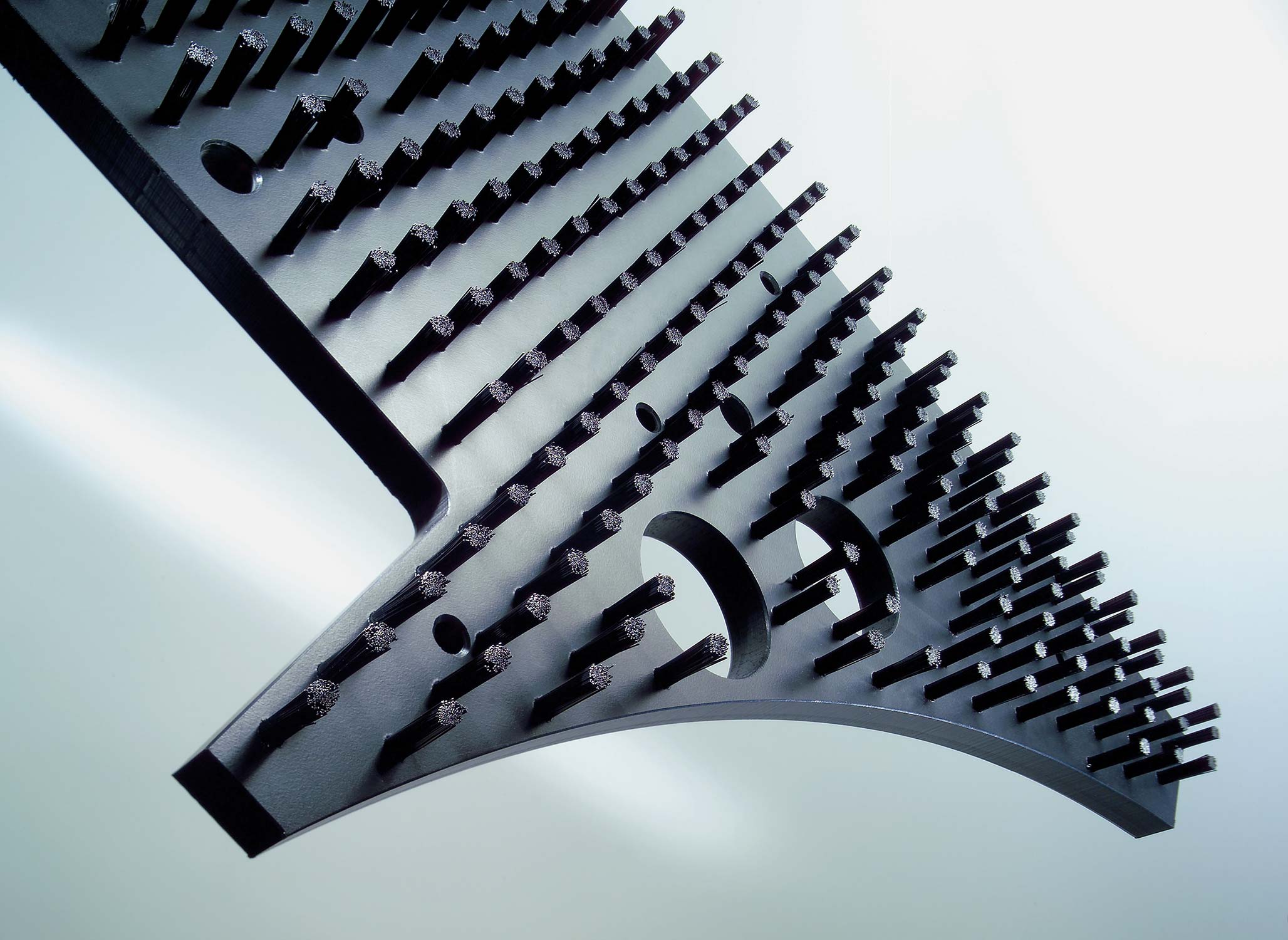

We offer the 3M Brushlon replacement brush for vibratory bowl feeders. Sliding brush, the replacement for the Brushlon 321B for bulk material handling. It allows uniform conveying of material in linear and spiral directions, as well as a simple change of direction thanks to the inclined position of the brush fibers.

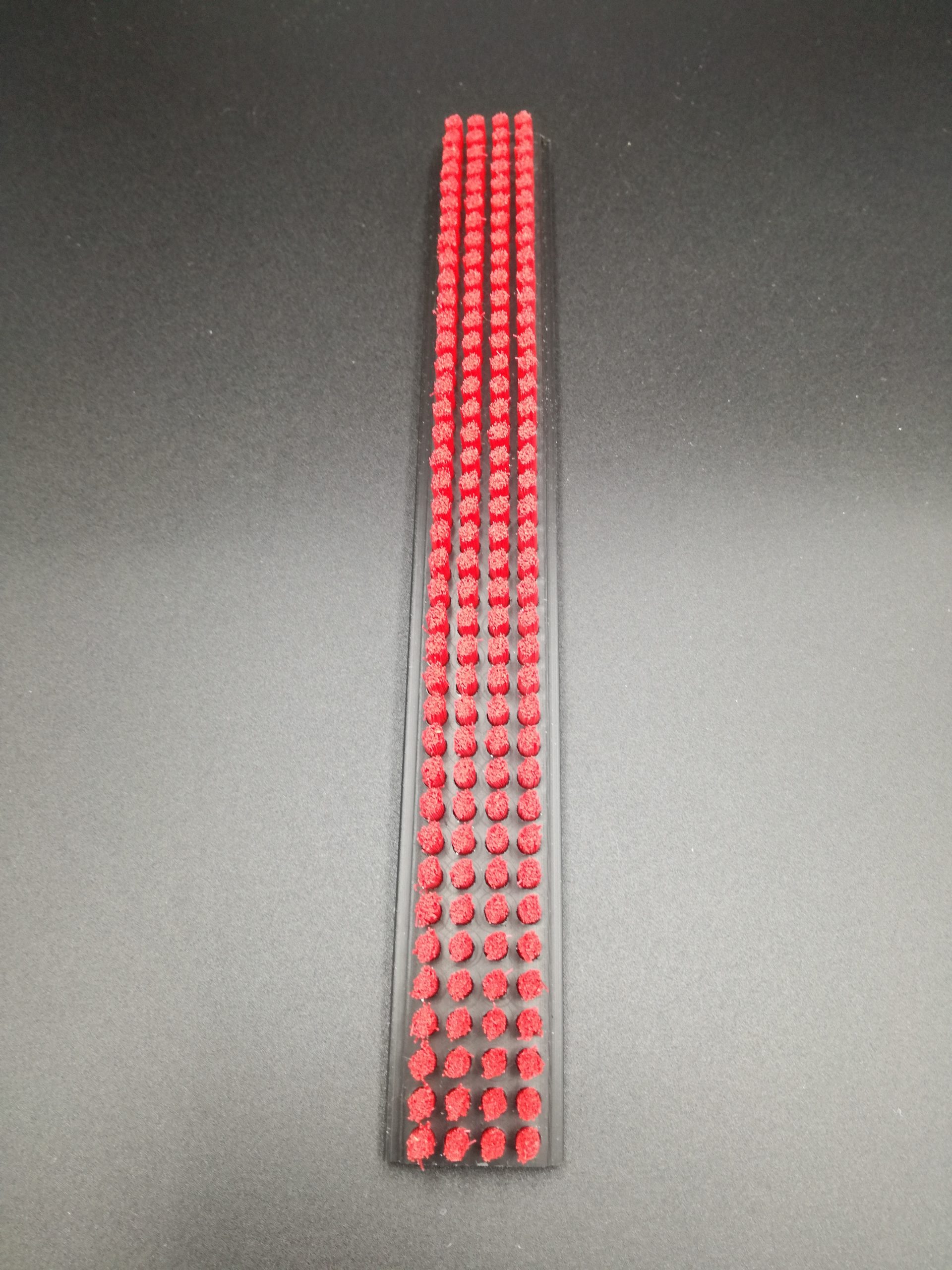

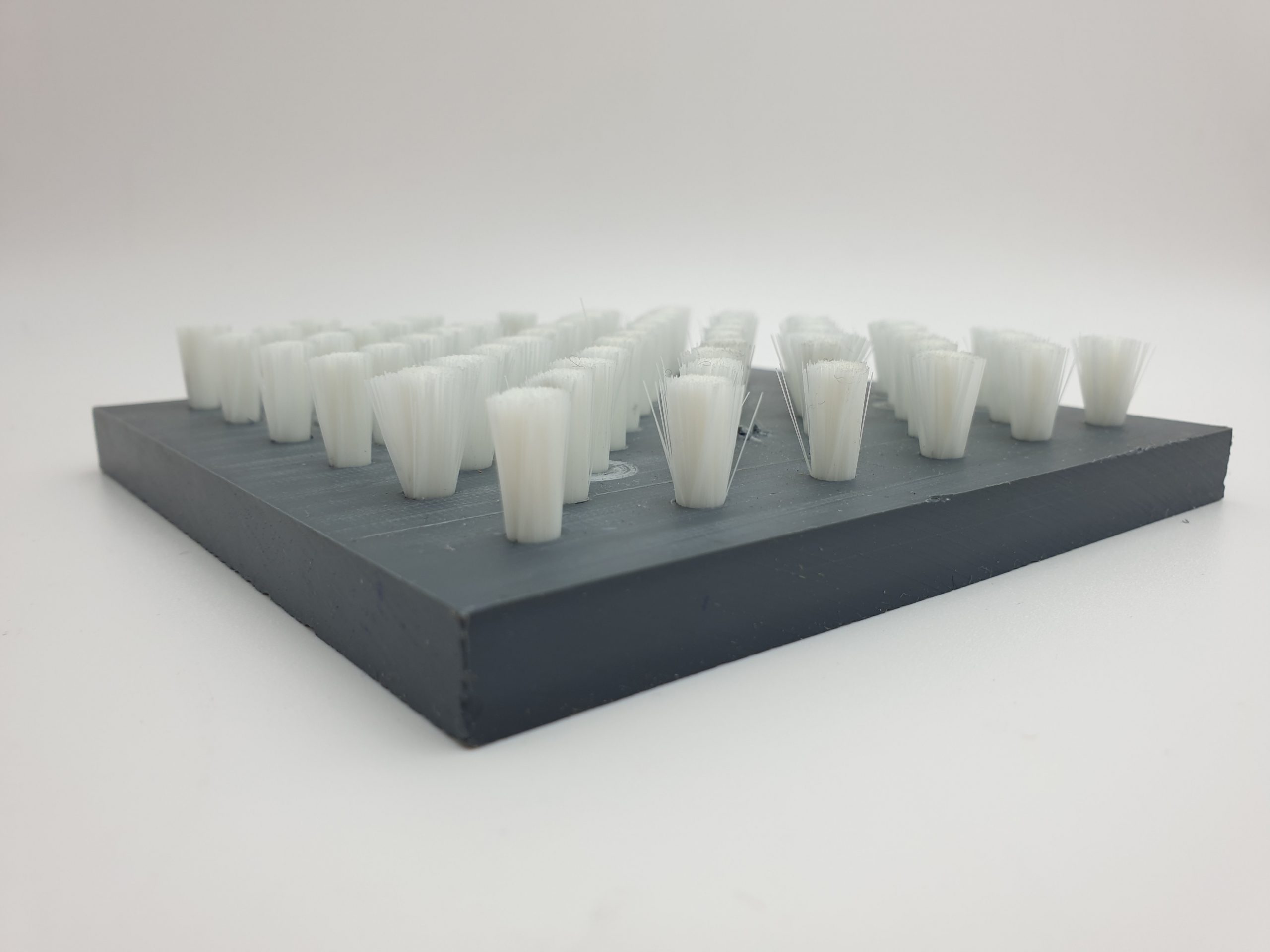

This brush will cover your trough and protect your bulk parts. It is a friction resistant material and will move the pieces along the in-line rail in the correct orientation for pick-up. It can be cut to size.

Product features:

• Uniform conveying of parts in different directions

• No damage to conveyed products due to soft fibers

• Noise reduction

• High stability

• Improved conveying performance increases productivity

• Triple conveying speed due to inclined fiber position

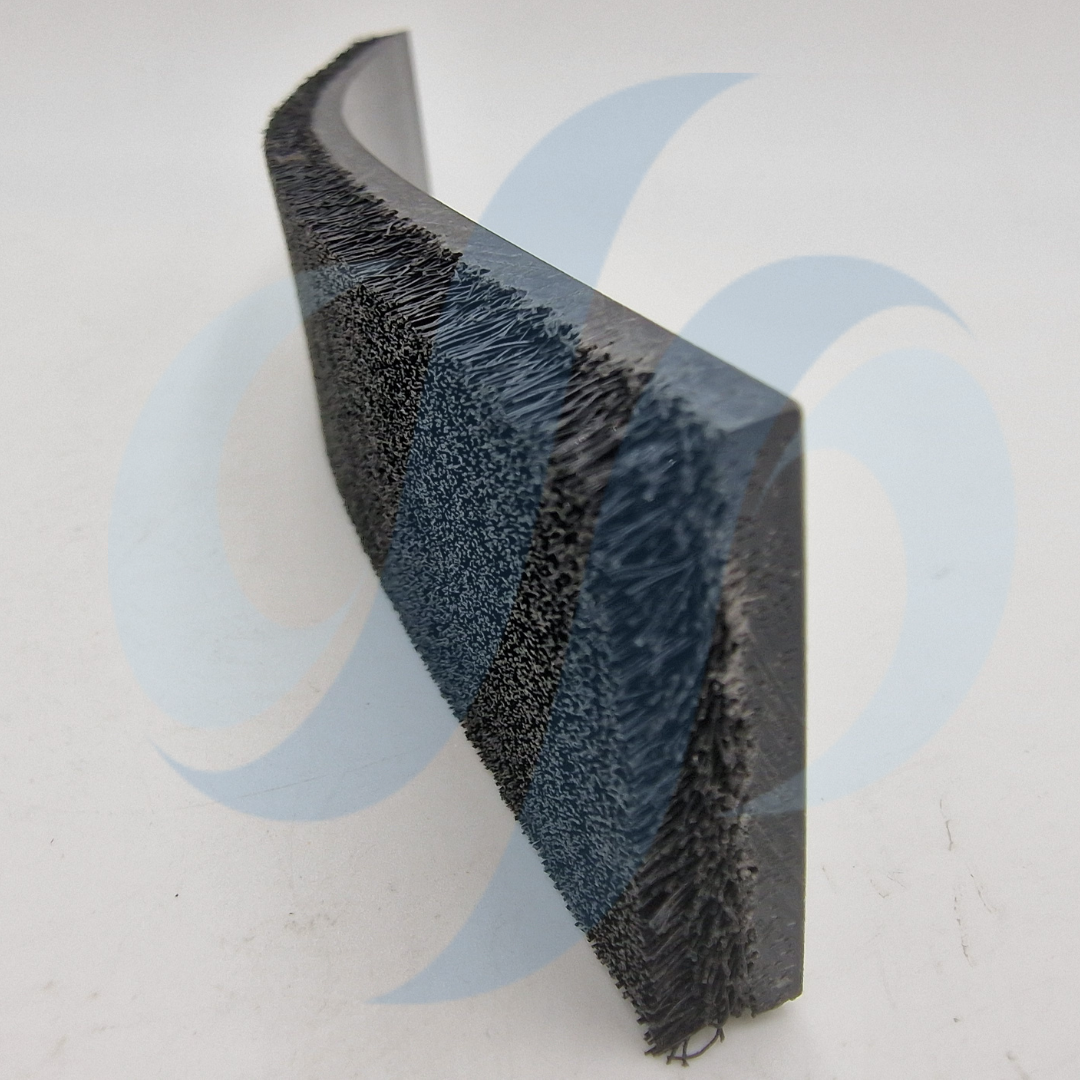

• High flexibility of body material

It can be cut to fit project dimensions and its short-cut nylon bristles are a good combination to reduce noise, help move parts and create non-slip surfaces.

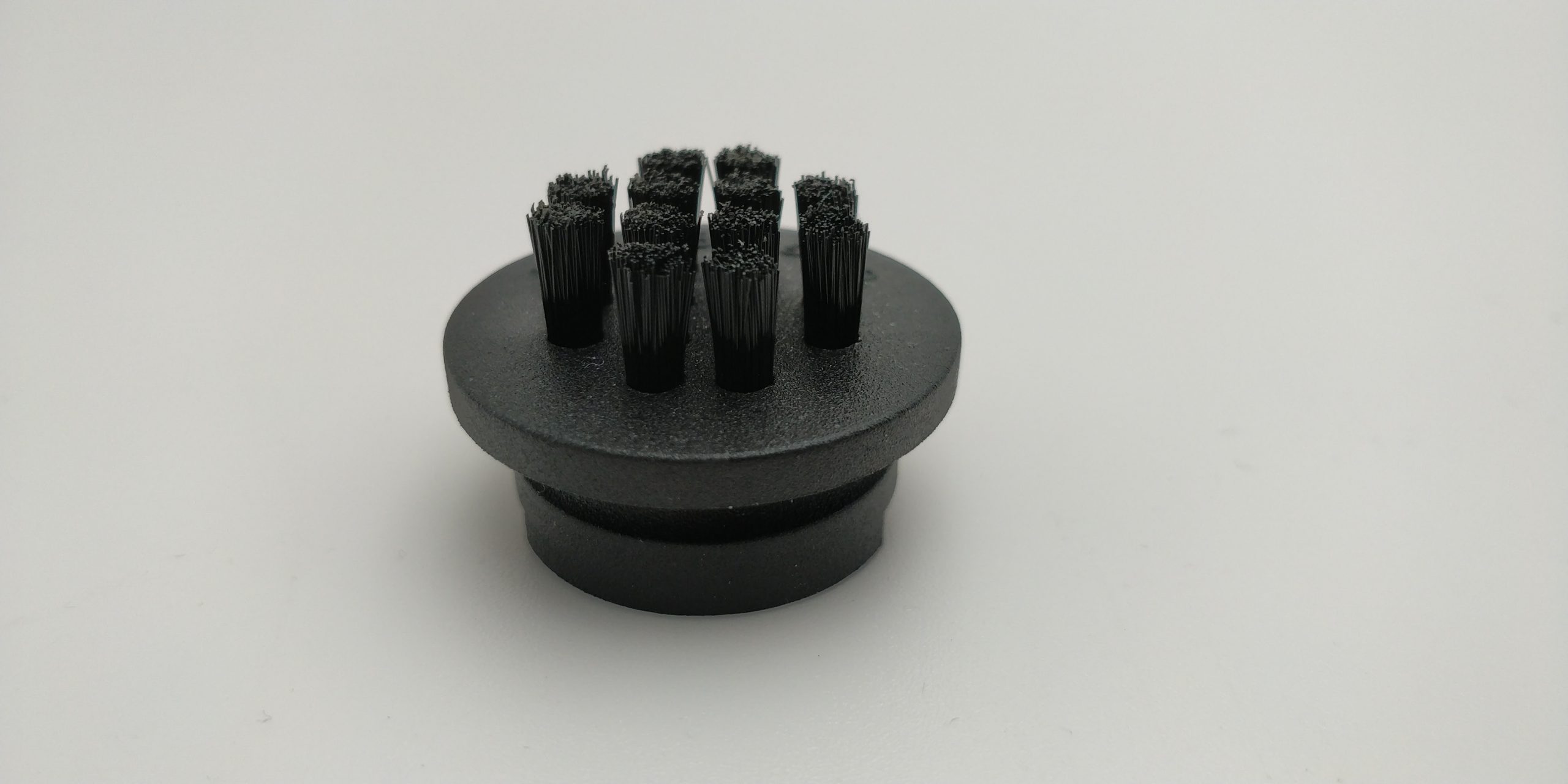

Sliding brush with inclined brush fibers

Ideal for applications including:

Sound dampening

Vibratory feeder lining

Vibratory conveying

Carrier roll cover

The surface of the vibrating conveyor brush is smooth and non-marking.

They can be secured / fixed by standard methods. We recommend using Velcro tape for optimum performance.

Pieces can be replaced as needed by being able to cut it, without the need to install a completely new panel.

Optimize your conveying processes; As a replacement for the Brushlon 321B, which is no longer manufactured by 3M, our sliding brush allows uniform conveying of material in linear and spiral directions, as well as a simple change of direction thanks to the inclined position of the brush fibers.

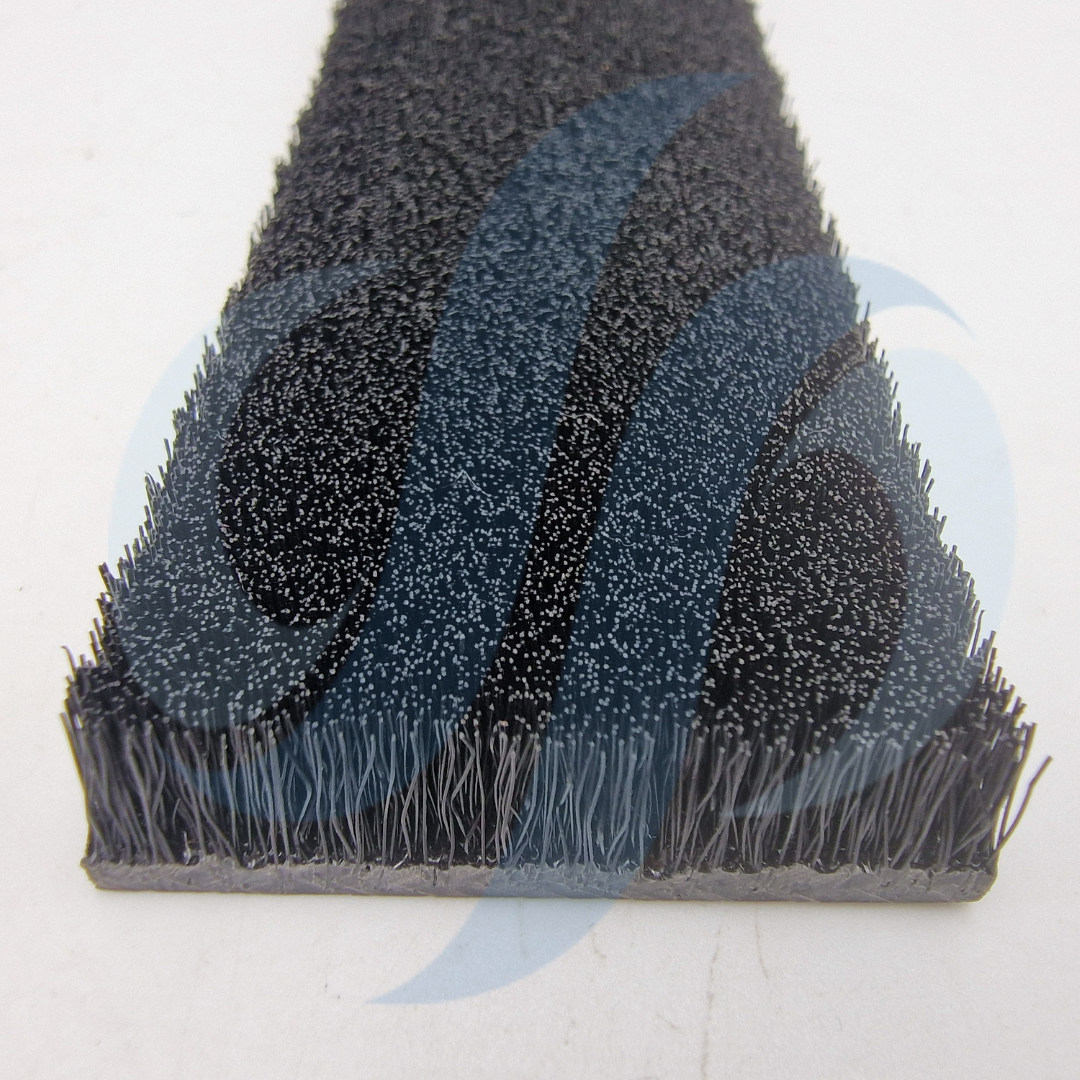

Small parts, such as bolts or nuts, are transported to their final position by vibration on the fiber tips.

The flexible brush base ensures optimum adaptability and protection in the system. The soft brush fibers also prevent scratches and abrasion on the conveyed material and thus reduce waste.

Flexible backing material and adaptable brush fibers reduce the noise level by up to 40 %.

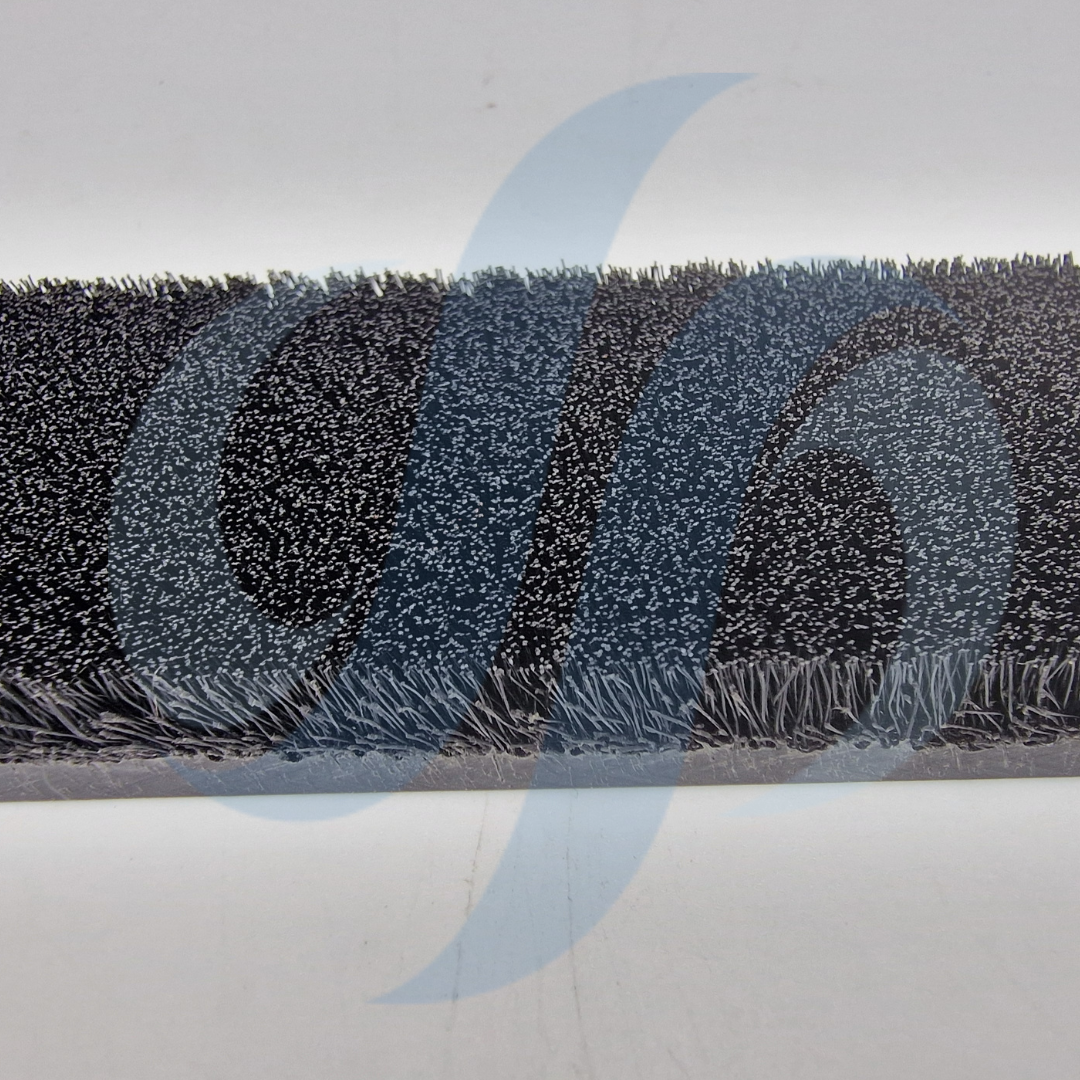

The uniform inclination of the fibers is constant from the base of the fiber to the tip and thus guarantees enormous stability during the conveying process.

The sliding planer offers you a comprehensive solution to your material handling challenges that combines efficiency, durability and productivity.

Consult our technicians for advice.

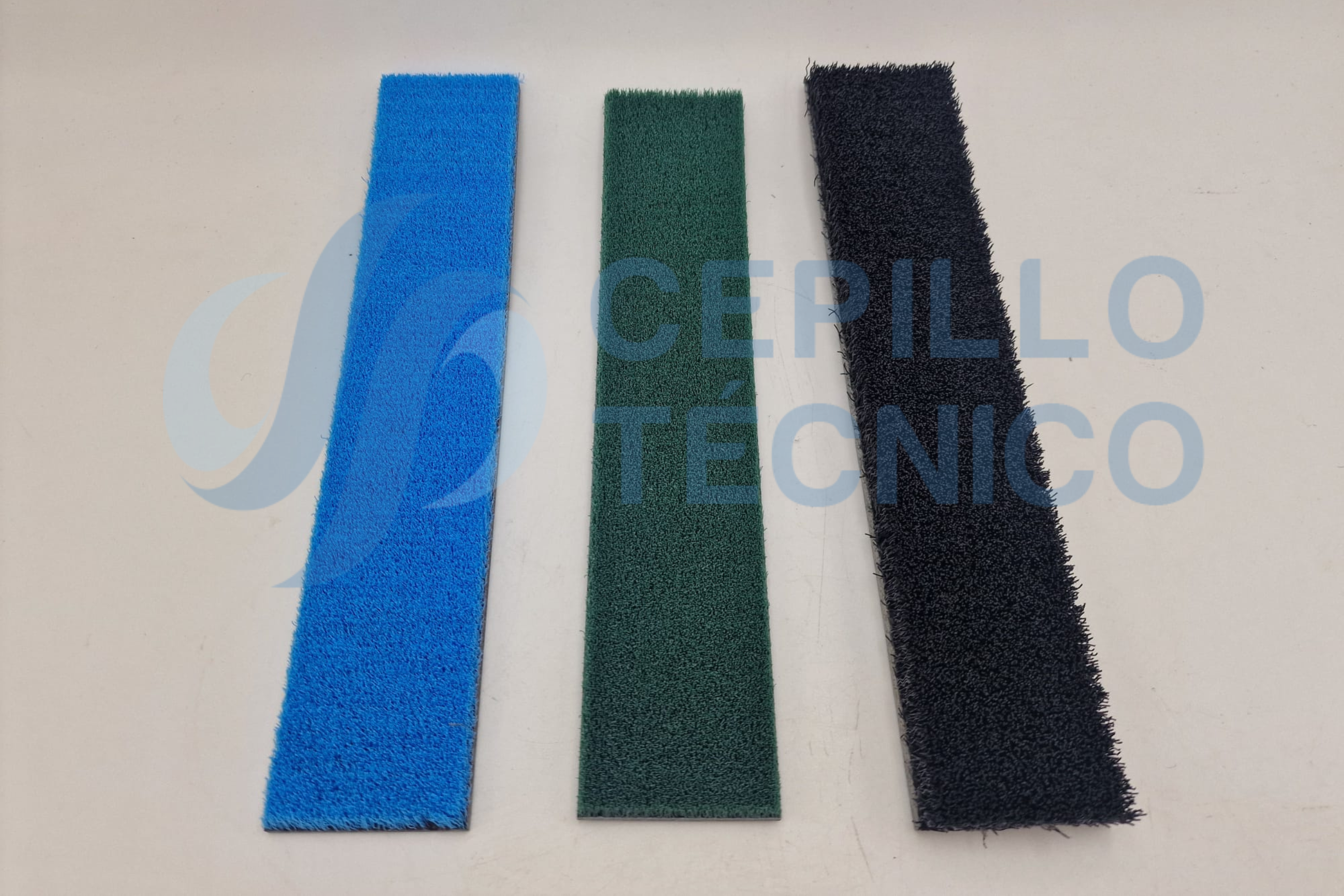

3 Models Available:

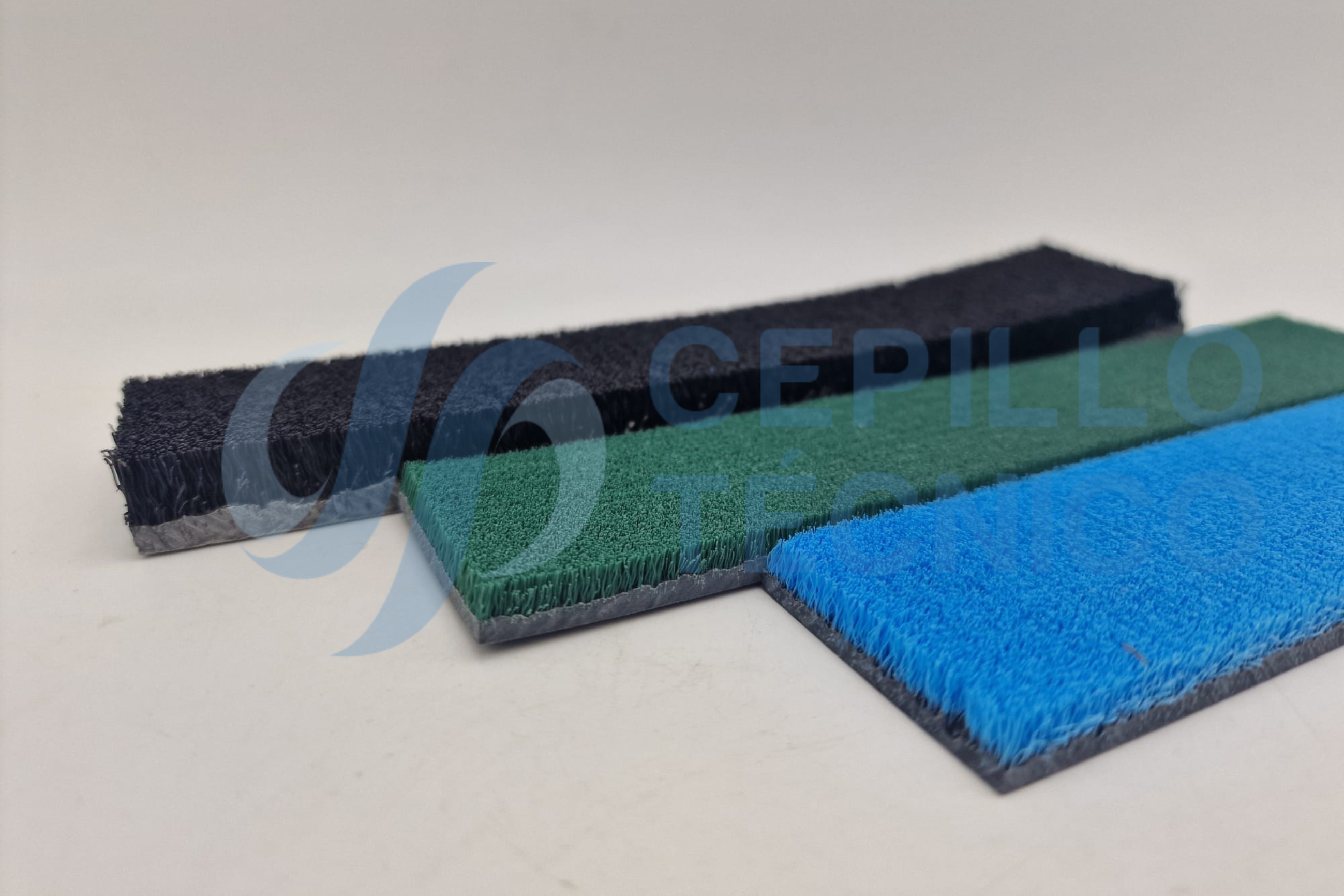

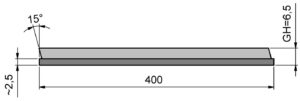

Model 615-K1

Body: Dark gray polyurethane

Fiber material: Polyamide 6 (PA6) green 0,15mm

Fiber output (FH): ~4 mm

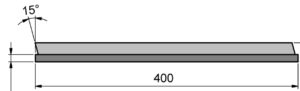

Inclination: 15°

Board size: 400 x 400 mm

Model 615-K1-FC Food Industry Suitable

Same as above but with Fiber material: Polyamide 6 Food grade certified (PA6) Blue 0,15mm

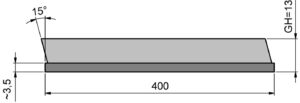

Model 1330-K1

Body: Dark gray polyurethane

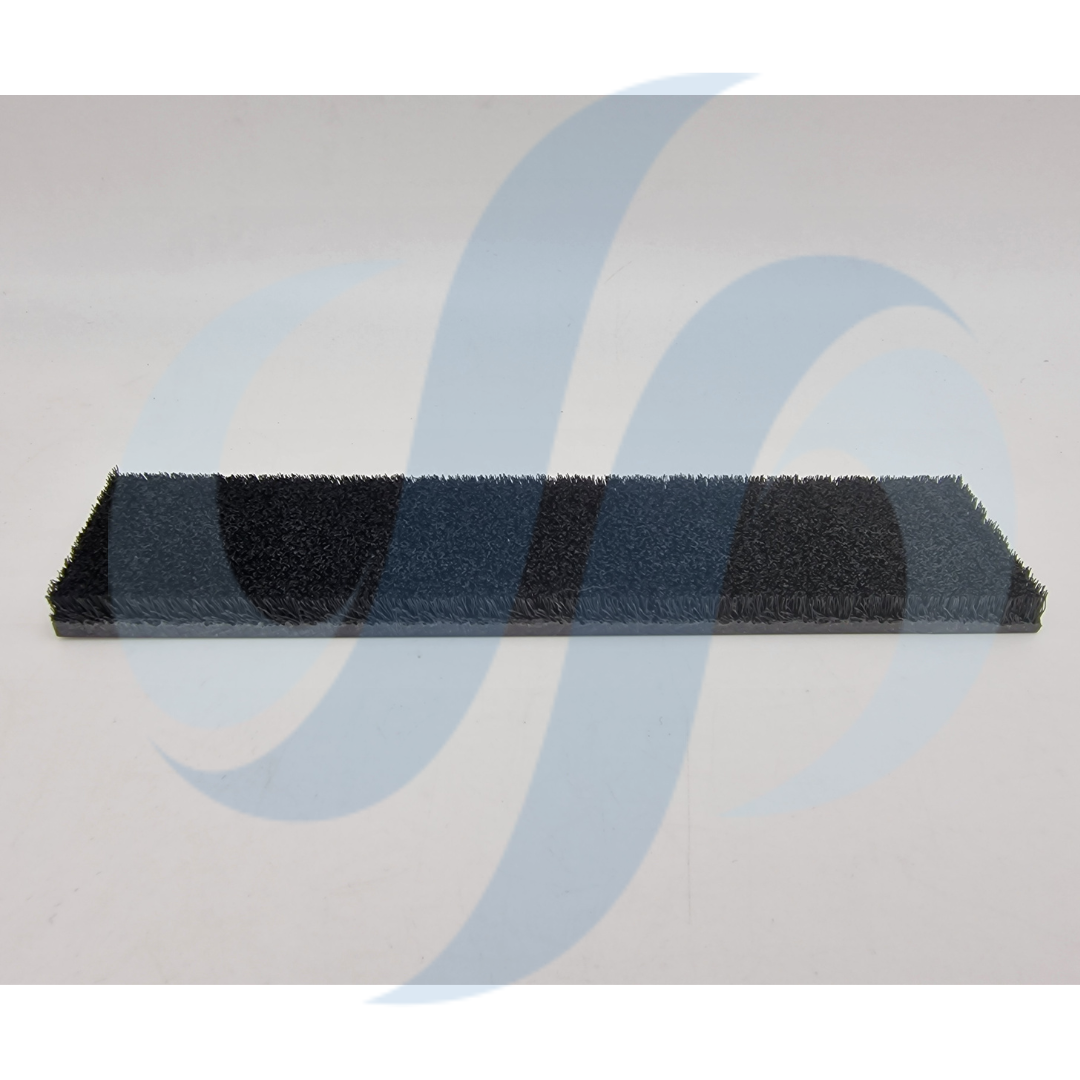

Fiber material: Polyamide 6 (PA6) black 0,30 mm

Fiber output (FH): ~9,50 mm

Inclination: 15°

Board size: 400 x 400 mm

Additional information

| Largo | 1, 2 ó 3 metros |

|---|