Brushes for cleaning moulds

Brushes for cleaning moulds

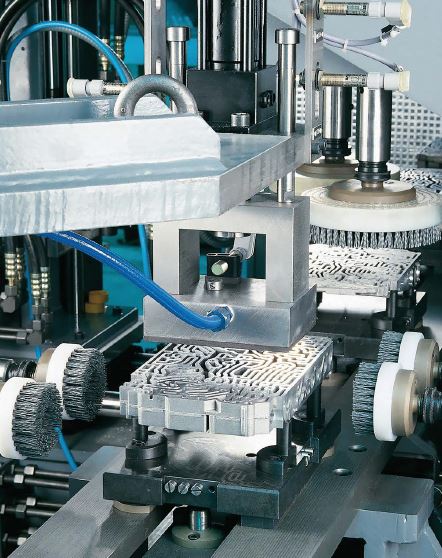

Mould cleaning

Remove dust and debris from the moulds before or after use.

Module cleaning is most common in building and construction and in raw materials. Brushes are used to clean moulds either before or after moulding, removing dust and material residues and thus ensuring the quality of the next product to be moulded.

Strip brushes with curved fibre tufts for cleaning edges or corners are widely used.

In the moulding sector, flexible brushes are often used due to the complex geometry of the moulds. To access the most difficult parts, we have brushes that can be attached to tools with or without a shaft; circular brushes, cup brushes, brush-type brushes, etc.

These brushes can be supplied with abrasive nylon fibres in different grit sizes (like sandpaper). Abrasive nylon does not scratch or alter the dimensions of the parts. The fibres are flexible and penetrate at all angles, allowing irregularly shaped parts to be brushed.

Disc brushes with abrasive nylon are integrated into numerous machines that clean without damaging parts, without marking or altering their size. The fibres are flexible and contain silicon carbide grains that facilitate cleaning by giving the brush greater scrubbing power.

Another type of brush used in mould cleaning is the interior cleaning brush for cleaning the interior holes of small or hard-to-reach parts. They remove rust, residue and adhesions from interior areas. They can be used manually or attached to portable or stationary machines. They may have a coupling thread.