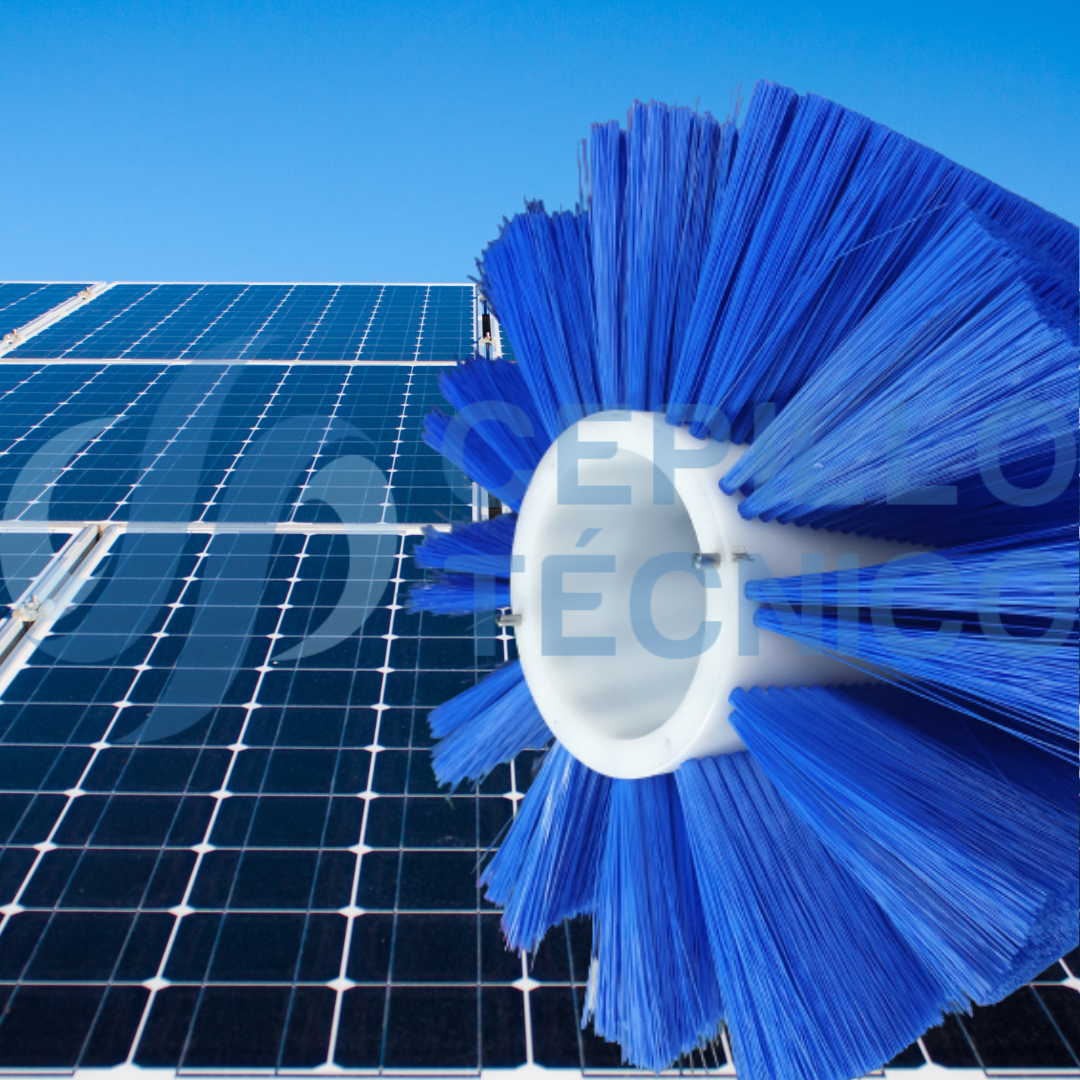

Brushes for washing solar panels and plates

Brushes suitable for washing solar panels and plates

The photovoltaic industry requires brushes that remove dirt without damaging photovoltaic cells, thus preventing loss of effectiveness. We have extensive experience in materials that are suitable for not scratching the panels, both in cylindrical brushes and strip brushes. We study each requirement, the

dimensions and weight of the brush, and ensure that it is suitable for each cleaning system. Washing with brushes for cleaning solar panels and plates on an industrial scale is currently a booming application.

At Cepillo Técnico, we have extensive experience in manufacturing brushes designed for cleaning and washing solar panels and plates with water.

Our customers mainly request large-diameter cylindrical brushes to cover very long shafts, as this allows them to clean as much surface area as possible in each pass. This is possible as long as weight is taken into account. As the shafts are very long, we must construct large but lightweight cylindrical brushes, with the lowest possible weight. We have extensive experience in this area and can offer our customers a range of models and advice.

We also have fibres that provide optimal cleaning without damaging the photovoltaic panels, thus restoring the solar panel’s full efficiency and performance.

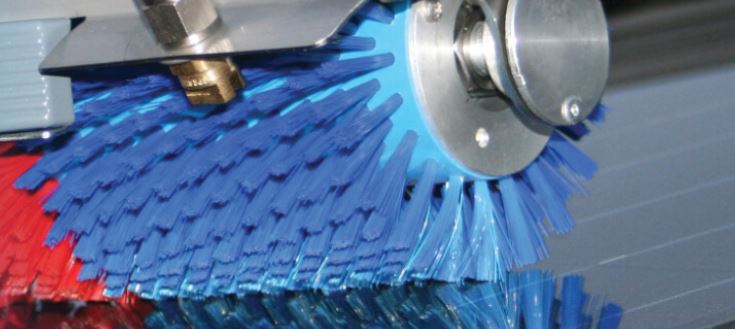

Cylindrical brush with plastic base and fibre inserted in tufts

Construimos los cepillos cilíndricos de base plástica con tubo hueco para minimizar peso. Además los hacemos modulares con unión estre sí mediante anclaje y pasador hembra / macho, esto facilita el transporte y el montaje de ejes largos de más de 4 metros de longitud.

We manufacture cylindrical brushes with a plastic base and hollow tube to minimise weight. We also make them modular, with female/male anchors and pins connecting them together, which facilitates transport and assembly of long shafts over 4 metres in length.

The fibre arrangement may vary in a staggered or spiral pattern to drag dirt towards one end.

It is best not to exceed a total brush diameter of between 490 and 500 mm in order to use standard materials and processes that allow for the most affordable price possible.

The helical fibre arrangement allows dirt to be swept to one side:

Spiral cylindrical brush with metal base

Cylindrical spiral brushes with metal bases are lightweight and easy to transport, as the compressed loose spirals can be supplied separately. The customer then extends the spiral along the shaft, leaving a certain amount of space between turns, and welds it in place at the beginning and end to secure it to the tube or shaft of the machine or cleaning arm.

The maximum total diameters we can manufacture for these spirals are between 250 and 350 mm. The metal core is made of stainless steel and the fibres are suitable for cleaning solar panels without scratching them. This is an interesting option that is becoming increasingly popular.