Brushes for cleaning counterpressure rollers

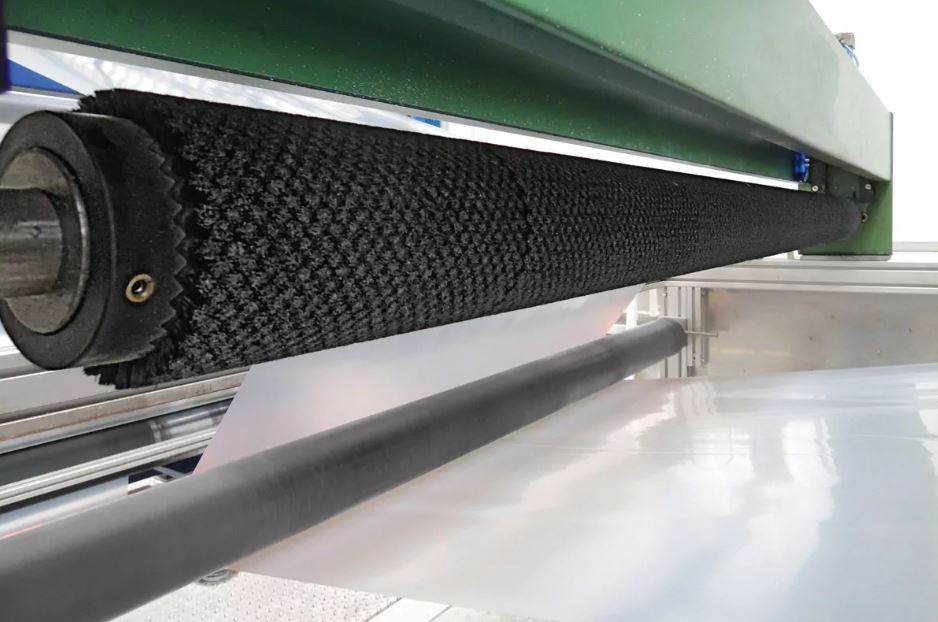

Brushes Counterpressure rollers

Counterpressure rollers

Counterpressure rollers: optimum counterpressure for perfectly perforated, crease-free results.

The counterpressure rollers are highly durable, suffer almost no wear and tear, and deliver excellent results in the final product, both in cold and hot perforation. Compared to conventional counterpressure rollers – rubber rollers and grooved metal rollers – the needles penetrate between the fibre strands during the needling process, thus minimising roller wear. The counterpressure roller consists of modular cylindrical brushes 100 mm long, which are easy to assemble. The shaft is covered with modular brushes, allowing for partial replacement in case of wear, thus extending the roller’s service life and reducing costs. The maximum length of 2,450 mm covers almost all requirements.

Technical specifications:

- Uniform pressure

- Minimal wear thanks to fibre coating

- Needles penetrate between the fibre tufts

- No marks thanks to special fibre technology

- Suitable for micro-perforation

- Replaceable fibre coating, extending service life and reducing costs

- Suitable for high temperatures

- Supply of complete rollers

- Short delivery times due to standardised parts

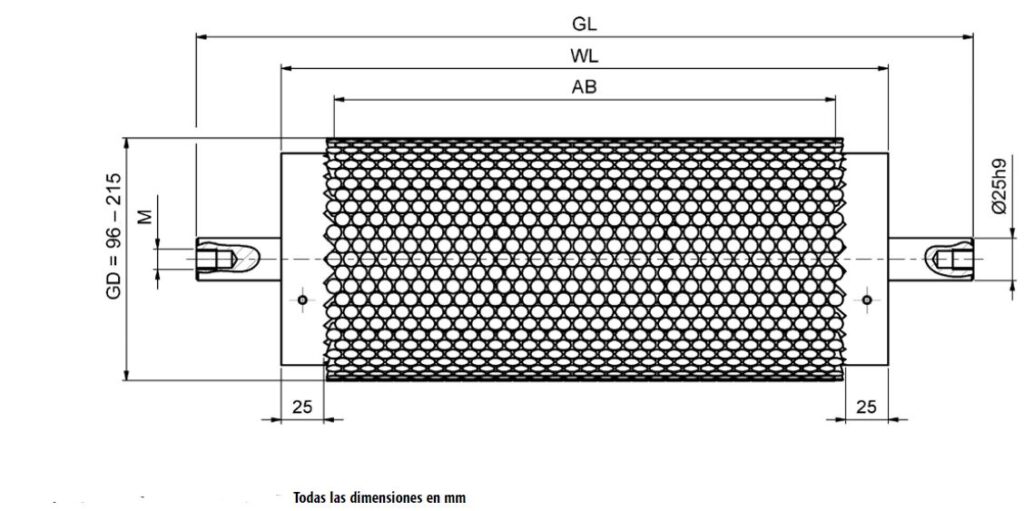

Max. GL / maximum roller length 2500 mm

Max. WL / maximum roller width 2450 mm

Max. AB / maximum working width 2400 mm

Ø / standard shaft diameter 25 mm

Standard fibre material PA 0.20/0.30 mm / corrugated black PA 0.20/0.30 mm

Ø / shaft diameter 75 mm

Ø base diameter 100 mm

Ø / total roller diameter 120/130 mm

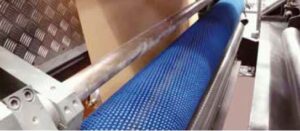

Counterpressure roller in the belt splicing device

Back pressure in hot drilling

Application with large needle spacing

Back pressure in cold drilling