Brushes for cleaning conveyor belts

Brushes for cleaning conveyor belts

Cleaning conveyor belts

Conveyor belts are widely used for all kinds of processes, sectors and material manufacturing, food processing, transport and sorting of goods or objects, etc.

Movement of raw materials in dedicated storage devices.

Transportation of raw materials to the production line.

Transfer the manufactured product to the packaging line.

Transportation of packaged goods to another area for shipment.

Its most significant uses are in the food industry, construction and aggregates, logistics and transport, furniture, wood and paper, airports, etc.

Conveyor belts are generally made of strong, durable materials such as nylon, polyester and rubber, which can be easily cleaned.

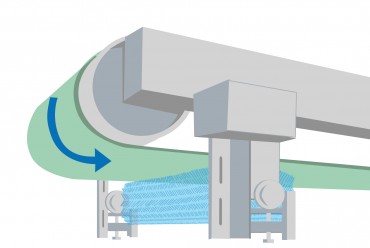

Cleaning conveyor belts using cylindrical brushes is one of the most widely used systems, which is also complemented by traditional scrapers and other cleaning systems. They can clean ribbed belts, Chevron belts, or embossed belts, among others.

Brushing removes debris immediately after the conveyor belt discharge point. The brush is usually placed on the return so that it does not interfere with the objects being transported.

Conveyor belt cleaning is common in almost all markets. Brushes clean conveyor belts after transporting products, thereby ensuring the quality of the next batch. We can adapt the brush to clean different types of waste, as well as smooth, ribbed or rough belts, by varying the brush fibre output, type and density in each case.

The arrangement of the fibres in the brush can also allow for sweeping or cleaning on the return of the belt, in a helical pattern to one side, etc.

This type of cleaning of conveyor belts and bands is carried out in many industrial sectors such as quarries, the timber industry, construction and, very widely, in the food industry, where we use materials suitable for the food industry with FDA/EU certificates for food contact.

Consult our technicians so that they can advise you on your specific needs.